86-025-5119 7362

Small compact size, easy mounting, space-saving, long service life An industrial Syringe Pump with high precision & high performance in micro-liquid transferring self-developed by Runze Fluid. Make step motor move in clockwise or counterclockwise by receiving instructions from the host computer. The circular motion is converted into linear motion by the trapezoidal screw to make the piston move up and down which realizes medical analysis equipment, chromatographic analyzers, food and beverages detection and analysis system, water quality on-line analyzer, petroleum detection equipment and biopharmaceutical extraction devices

| Accuracy | ≤1%@100% (rated stroke) | |

| Precision (Repeatability) | 0.3%-0.7%@100% (rated stroke) | |

| Service life | 3 million times no leakage (media: water; 1 rated stroke = one time) | |

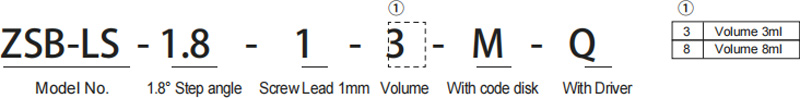

| Volume | 3ml | 8ml |

| Rated Stroke (control steps) | 18mm(3600steps) | 19.2mm(3840steps) |

| Maximum speed | 600rpm | 300rpm |

| Linear speed | 0.017-10mm/s | 0.017-5mm/s |

| Running time (per rated stroke) | 1.8-1080s | 3.84-1129s |

| Resolution | 0.005mm/0.833μl | 0.005mm/2.083μl |

| Syringe ID | 14.55mm | 23.03mm |

| Actuator | Trapezoidal screw (Lead 1mm) | |

| Wetted Material | Borosilicate glass, PCTFE valve head, PTFE piston | |

| Max. Pressure | Positive: 0-0.8Mpa, Negative:0-0.06Mpa, (retention time based on test) | |

| Channel | Single channel | |

| Connection | 1/4-28UNF | |

| Baud rate | RS232/RS485:9600bps / 19200bps / 38400bps / 57600bps / 115200bps CAN:100Kbps/200Kbps/500Kbps/1Mbps | |

| Address & Parameter setting | Via Communication | |

| Max power | 15W | |

| Power supply | DC24V/3A | |

| Operating temperature | 5℃~55℃ | |

| Operating humidity | ≤ 80% relative humidity, non-condensing | |

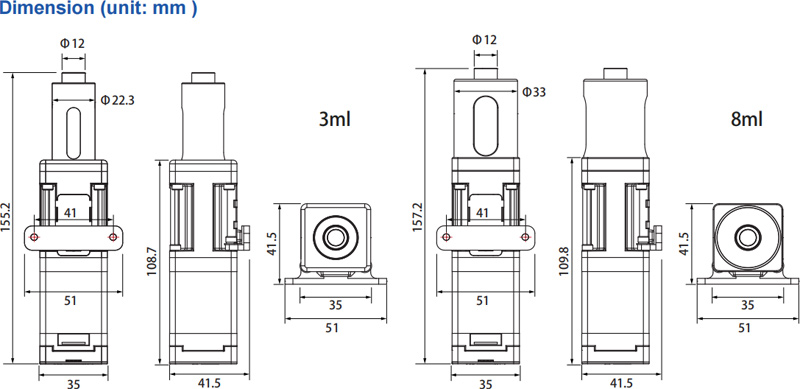

| Dimension (L*W*H) | 51*41.5*155.2mm | 51*41.5*157.2mm |

| Net Weight | 0.56kg | 0.62kg |

| Address setting | Address settable via serial port |

| Baud rate setting | RS232/RS485/CAN baud rate settable |

| CAN destination address setting | When multiple devices controlled in paralleling, any device can be set with priority address |

| Speed setting | 3ml:from 1 rpm to 600 rpm 8ml:from 1 rpm to 300 rpm (There are difference for gas, liquid and models) |

| Subdivision setting | subdivision 2-32 are settable |

| Reset interior data | Factory reset |

| Parameter query | Query address, speed, subdivision, baud rate, etc. |

| Version query | Query current firmware version |

| Motor direction | CW/CCW settable |

| Reset | Return piston to the origin/home position |

| Strong stop | Strong stop the running motor |

| Motor status query | Detect current motor status |

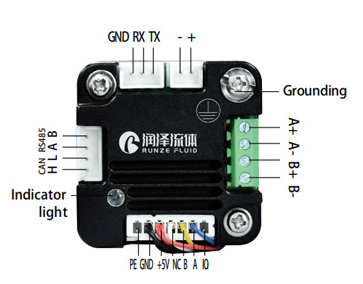

| Port | Description | Port | Description |

| + | DC24V Positive | A+/A- | Phase A wiring |

| - | DC24V Negative | B+/B- | Phase B wiring |

| TX | RS232 Data Input | IO1 | IO1 Optocoupler signal |

| RX | RS232 Data Output | A | Encoder Phase A |

| GND | RS232 GND | B | Encoder Phase B |

| H | CANH | NC | Temporary is not enabled |

| L | CANL | +5V | Power positive |

| A | RS485A | GND | GND |

| B | RS485B | PE | Grounding |